Learn more about

Zoom projection lens for automotive headlights

1. Objective

The primary objective of this project is to develop a high-performance zoom lens for a cutting-edge, high-resolution, glare-free headlight. This advanced zoom lens will later facilitate the exploration of various use cases utilizing sophisticated projection technology within a vehicle headlight.

2. Background

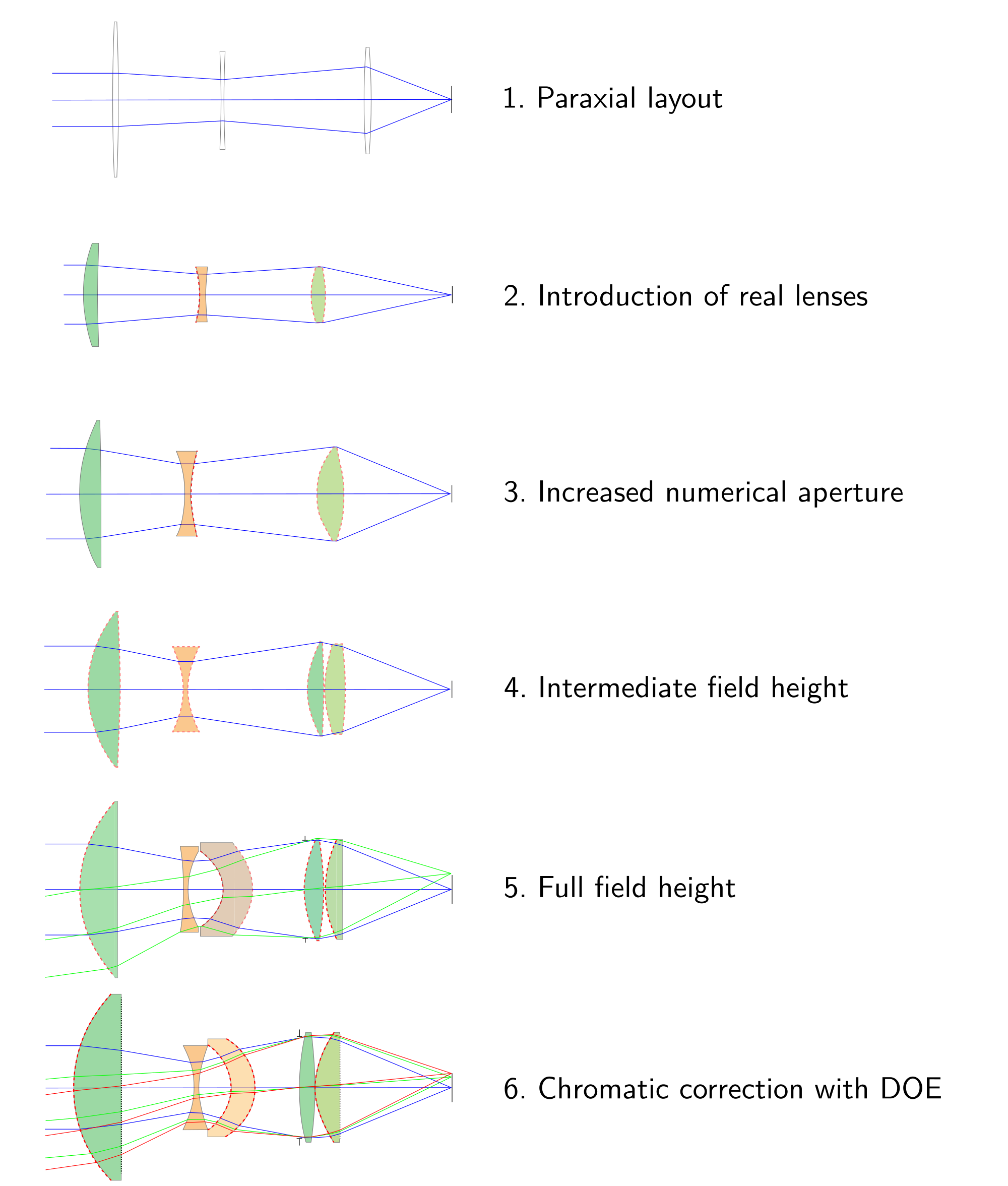

Glare-free high beam is the ability to mask-out oncoming or preceding vehicles to avoid glaring the drivers of other vehicles. There are different approaches to increase the resolution of headlight systems.

One promising approach utilizes Texas Instruments DLP® technology, which is a digital image technology used in projection applications such as cinema projectors and conference room projectors and became available for the automotive industry in 2015. The centerpiece of DLP®-technology is the digital micromirror device (DMD), which is an array of millions of microscopic mirrors, working as addressable pixels.

3. Optical Design of a Zoom Lens

Basic principle of a three unit zoom lens

An intermediate image is produced by the first lens unit, serving as the object for the second lens unit. The second lens unit is movable along the optical axis and

performs the magnifying operation. The third lens unit is used for both, the imaging and the compensation of focal shift accompanying any zoom motion.

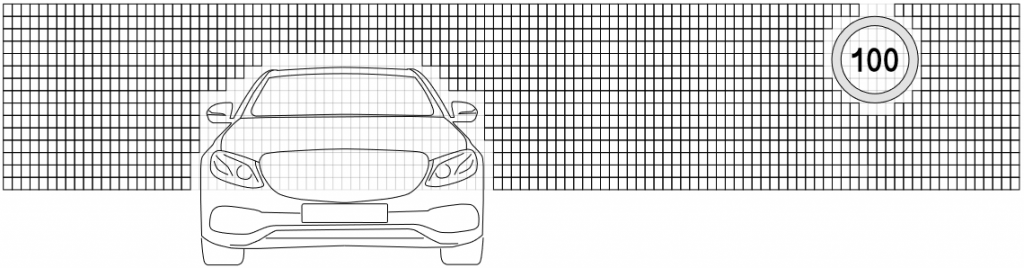

The figure above illustrates the magnifying operation of a three-component zoom lens, showing the positions of intermediate images at various zoom settings. The focal length of the zoom lens changes from wide-angle to telephoto. It can be seen that the magnification of the second lens unit changes from -0.5 to -2 while the variator lens is shifted towards the image side. The third lens unit is moved only a small amount along the optical axis to compensate the focal shift. At the mid position where the magnification equals -1, the compensator lens is nearest to the image surfaces. This ensures, that there is no zoom position that requires the compensator to be closer to the image surface.

Design strategy

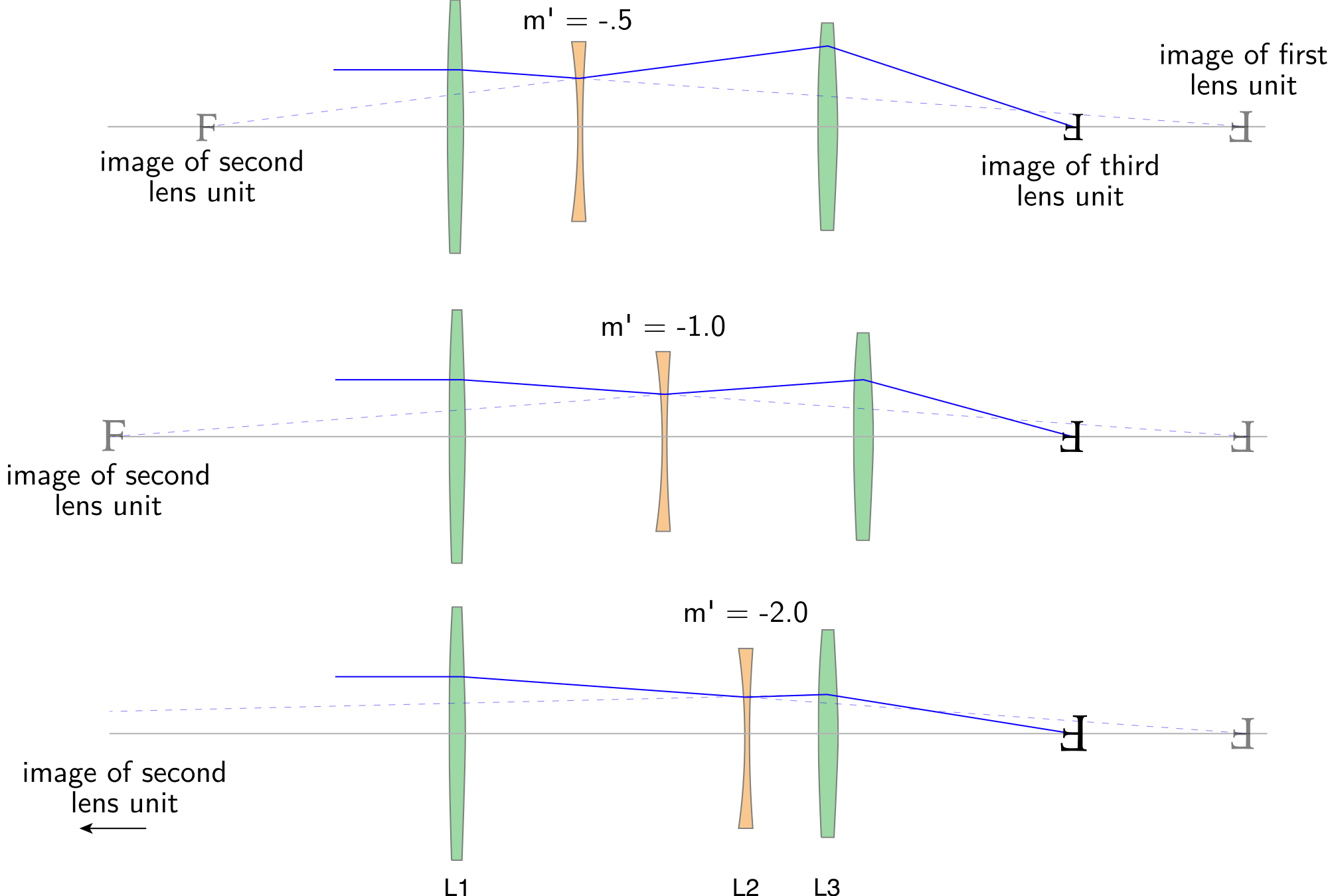

The system in the optical design software (i.e. Zemax ® or Quadoa) is reoriented so that the DMD chip functions as the image plane, with the object positioned at infinity. This approach prevents ray tracing failures and optimization delays that can occur when starting from the high numerical aperture side, where small changes in the critical rear part of the system are problematic. Since the spot-based performance criterion is calculated on the DMD plane, it can be directly compared to the actual pixel size. During the initial design phase, the system is evaluated for a single wavelength. Once the field of view and numerical aperture requirements are met, chromatic correction is addressed in the subsequent phase.

- Start with the paraxial layout for a three element zoom system.

- Replace the ideal lenses by real, spherical PMMA lenses using the simplified lensmaker’s equation. Numerical optimization on-axis for wide-angle, mid and telephoto zoom-positions.

- Enlarge the numerical aperture and the field of view to an intermediate size by adding aspherical surfaces in the rear part of the system.

- Add a lens to the imaging unit and optimize for growing numerical aperture and field of view.

- Add a lens to the varying unit and optimize for the specified field of view.

- Introduce diffractive surfaces (DOE) and optimize for the specified spectral range.

Tolerancing

Since the manufacturing process inevitably introduces deviations from theoretical values, it is essential to consider the impact of these errors on optical performance. Tolerance analysis provides a realistic estimate of the achievable performance of the manufactured zoom lens. This analysis must account for the set of tolerances defined by the producer’s capabilities (see for example Asphericon). Using these parameters, the optical design software calculates the negative effects of deviations for each element, considering factors such as radius tolerances, thickness tolerances, surface tolerances, decentering tolerances, and material tolerances.

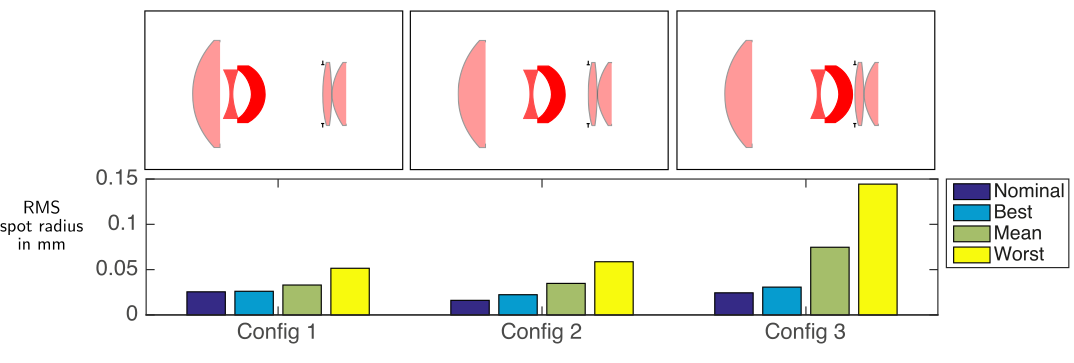

To allow for less strict tolerances, focus compensation is enabled, meaning that the assembled zoom lens must be capable of being focused. The tolerance analysis identifies which surface or element tolerances have the greatest impact on optical performance and provides parameters for the statistical distribution of systems affected by these tolerances. The criterion for this analysis is the RMS (root mean square) spot radius. The following figure shows the nominal, best, mean, and worst values for the RMS spot radius across three zoom positions.

Zoom motion curve

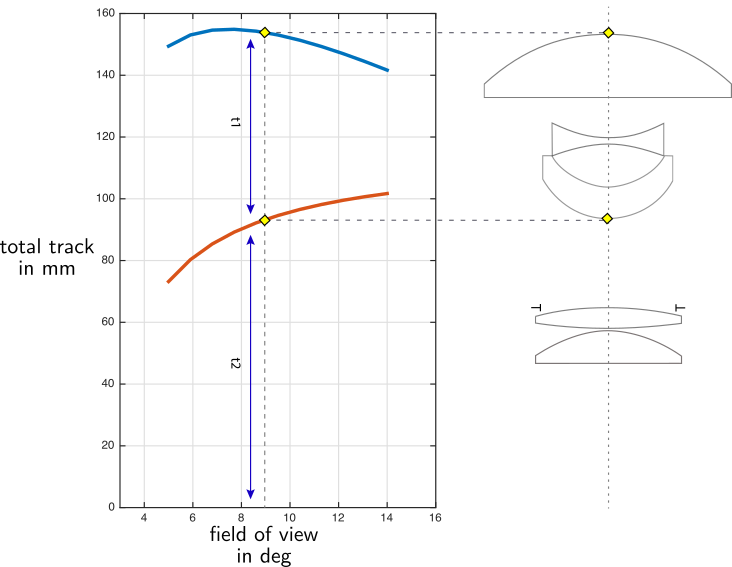

During the zoom motion, the distances between the lens units of the zoom lens have a nonlinear relationship. To determine these distances, an optimization procedure is used, where the distances serve as variables and the field of view is included in the merit function. This optimization is performed for ten intermediate zoom positions, after which the resulting distances between the lens units are interpolated.

4. Mechanical Design

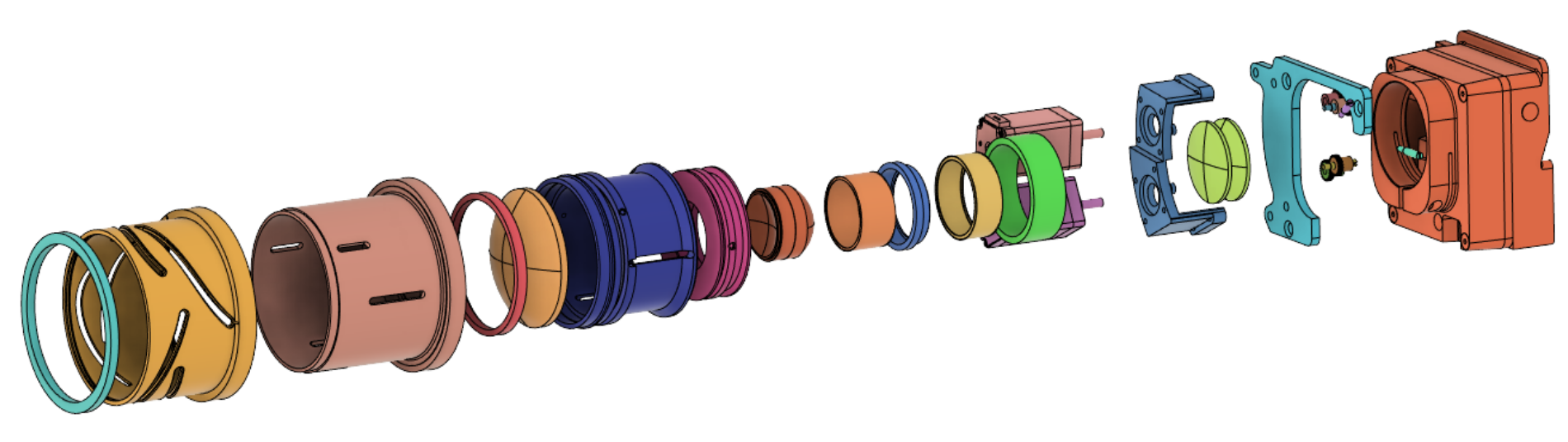

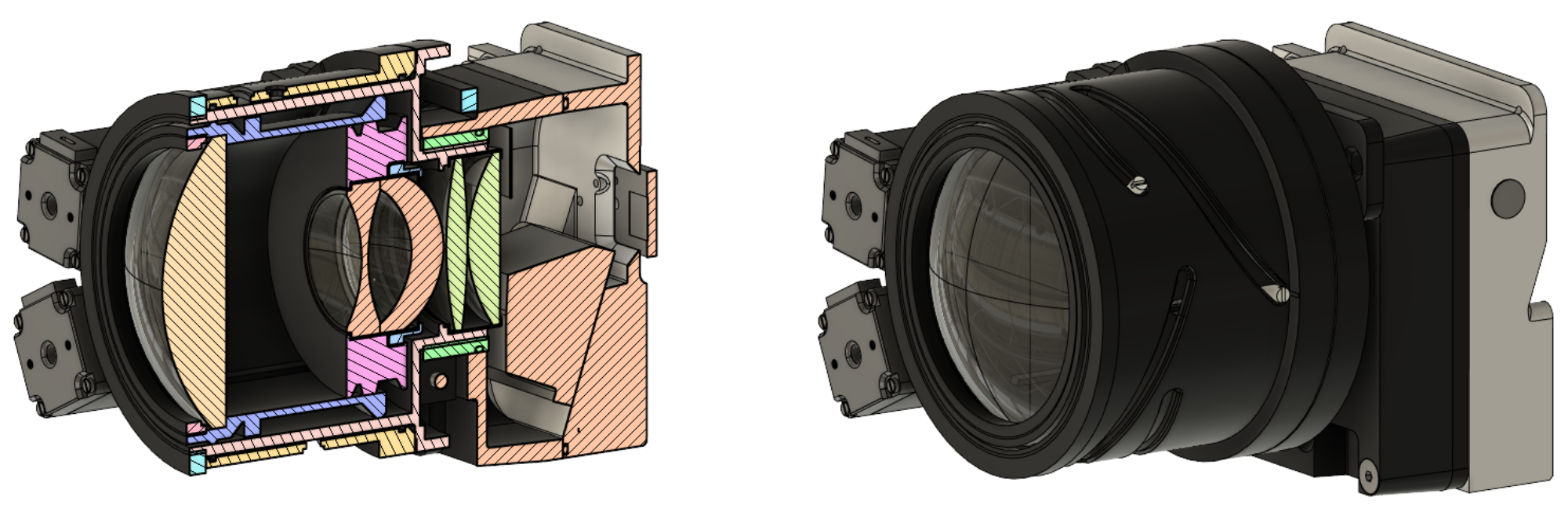

The purpose of the mounting system is to secure the individual lenses and ensure their correct positioning during zooming. The mechanical design is based on a basic cam mechanism, with the zoom motion paths of the lens groups cut into the shaft.

All individual lens groups are mounted in cylindrical components that can move along the optical axis. The component holding the variator lens unit moves inside the compensator lens tube, which in turn moves within the main barrel where the imaging lens group is mounted. Both the variator and compensator components feature three cams each, which follow the paths cut into the cam guide and cam shaft, ensuring the necessary coupled movement. For focusing, the entire zoom barrel needs to move relative to the headlight module. Therefore, the zoom barrel is threaded into a ring inside the headlight module.

The following figure illustrates the disassembled mounting system with all major components. For zooming and focusing two stepper motors are incorporated. They are attached to the headlight module, providing rotational motion to both the zoom barrel and the cam shaft, ensuring precise control and movement.

The cam shaft paths are designed to ensure that the field of view changes linearly with the amount of rotation. For focusing, the pitch of the thread ring that holds the zoom barrel determines the relationship between rotation and linear translation.

5. Result

In conclusion, the projection performance of the zoom lens has proven to be sufficiently robust to examine and evaluate use-cases for next-generation high-resolution headlights in future research projects. The system has been successfully integrated into a test vehicle, enabling further investigation and exploration of additional use cases, paving the way for advancements in automotive lighting technology.